We recover/extract vanadium contained in electrostatic precipitator soot (EP soot), which is an industrial waste of petroleum coke (PC) thermal power plants, in the form of ammonium metavanadate (AMV). It is a raw material for electrolytes. At the same time, valuable resources other than AMV, such as NH3, gypsum, etc. can also be recovered.

Currently, we are developing technology to recover vanadium from unused resources other than EP soot (eg, waste catalysts, etc.).

Electrostatic precipitator soot (EP soot)

Ammonium metavanadate (AMV)

As a process for manufacturing the electrolyte, first, we produce tetravalent oxide (V2O4) by the calcination process in the reduction furnace through the AMV purification process that removes impurities from the AMV raw material.

Impurities are further removed from this tetravalent oxide (V2O4), and a 3.5-valent electrolyte is produced in

an electrolytic reduction tank.

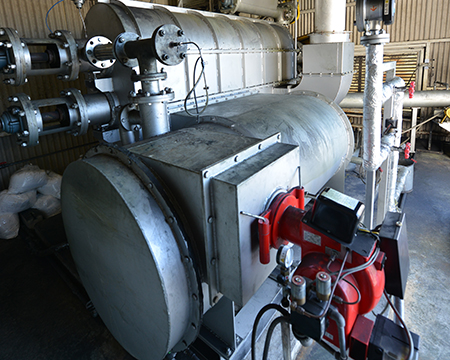

Calcining furnace

Produced electrolyte

The vanadium electrolyte changes in valence and color depending on the state of charge.